InfinityQS ® solutions-ProFicient™ and Enact ®-automate chart creation and help you optimize processes faster.

#Xbar r vs xbar s manual#

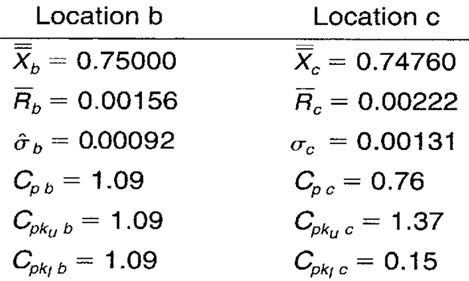

This example provides a deep dive into the manual calculations behind the group Xbar-R chart. This is why the group Xbar-R chart is selected. Although the dimensions of the poppet could also be monitored using three separate Xbar-R charts-one for each dimension-quality assurance wants to monitor the diameter using only one chart. To check the uniformity, three OD measurements arc taken on each poppet at locations a, b, and c. Therefore, uniformity of the OD is designated as a key characteristic. Rejection rates due to inconsistent ODs have been unacceptably high. Ī poppet is manufactured on a screw machine. Three OD key characteristics on a poppet. Review the following example-an excerpt from Innovative Control Charting 1-to get a sense of how a group Xbar-R chart works.įigure 1. Group Xbar and range (Xbar-R) charts help you assess changes in averages and the range of averages across measurement subgroups for a characteristic. Process Capability (Cp) and Performance (Cpk) Chart.Individual X-Moving Range (IX-MR) Chart.SPC Glossary: Quality Management Reference.Capability and Cpk Manufacturing Charts.Statistical Process Control (SPC) Implementation.

#Xbar r vs xbar s how to#

How to Choose a Manufacturing Quality Intelligence Platform.How to Sell Your Quality Management Plan.How to Use Quality Metrics to Improve Quality Management in Manufacturing.Quality Management Principles to Build Your Discipline.Digital Transformation in Manufacturing: The Role of Quality.Elevating the Importance of Quality Control in Manufacturing.Dynamic Remote Alarm Monitoring Service (DRAMS).ProFicient on Demand-Dedicated Subscription.

The following illustration shows an example of creating an XBar-S chart in iMonitor Designer using the SPC options on the left side of the window. When you select the SPC (Statistical Process Control) category in the lower-left of the iMonitor Designer window, the Toolbox area shows options for creating XBar-R and XBar-S charts as shown in the following illustration. You can create SPC XBar-R and XBar-S charts in iMonitor Designer to display in real-time dashboards. Create XBar-R and XBar-S charts in iMonitor Designer These charts are typically used to plot the subgroup mean for a larger subgroup and the standard deviation. Use an XBar-S chart when your sample size is 10 or more ( n≥10) and a lot of data is readily available, for example on high-speed production lines where many measurements can be gathered quickly.Īn XBar-S chart shows both the mean value (XBar) chart and the standard deviation (S) chart.

XBar-S charts are identical to XBar-R charts except that the R (range) is replaced by an S (standard deviation).Īn XBar-S chart plots the average and the sample standard deviation of individual values in a subgroup. XBar-R charts are very useful because they show changes in both the mean value and the dispersion of a process at the same time, making it a very effective way to check for abnormalities in a process.

0 kommentar(er)

0 kommentar(er)